อะไหล่ฟรี

อะไหล่ฟรี

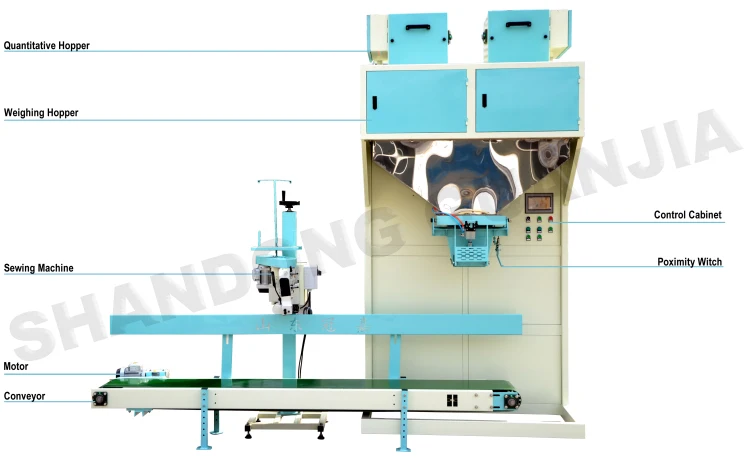

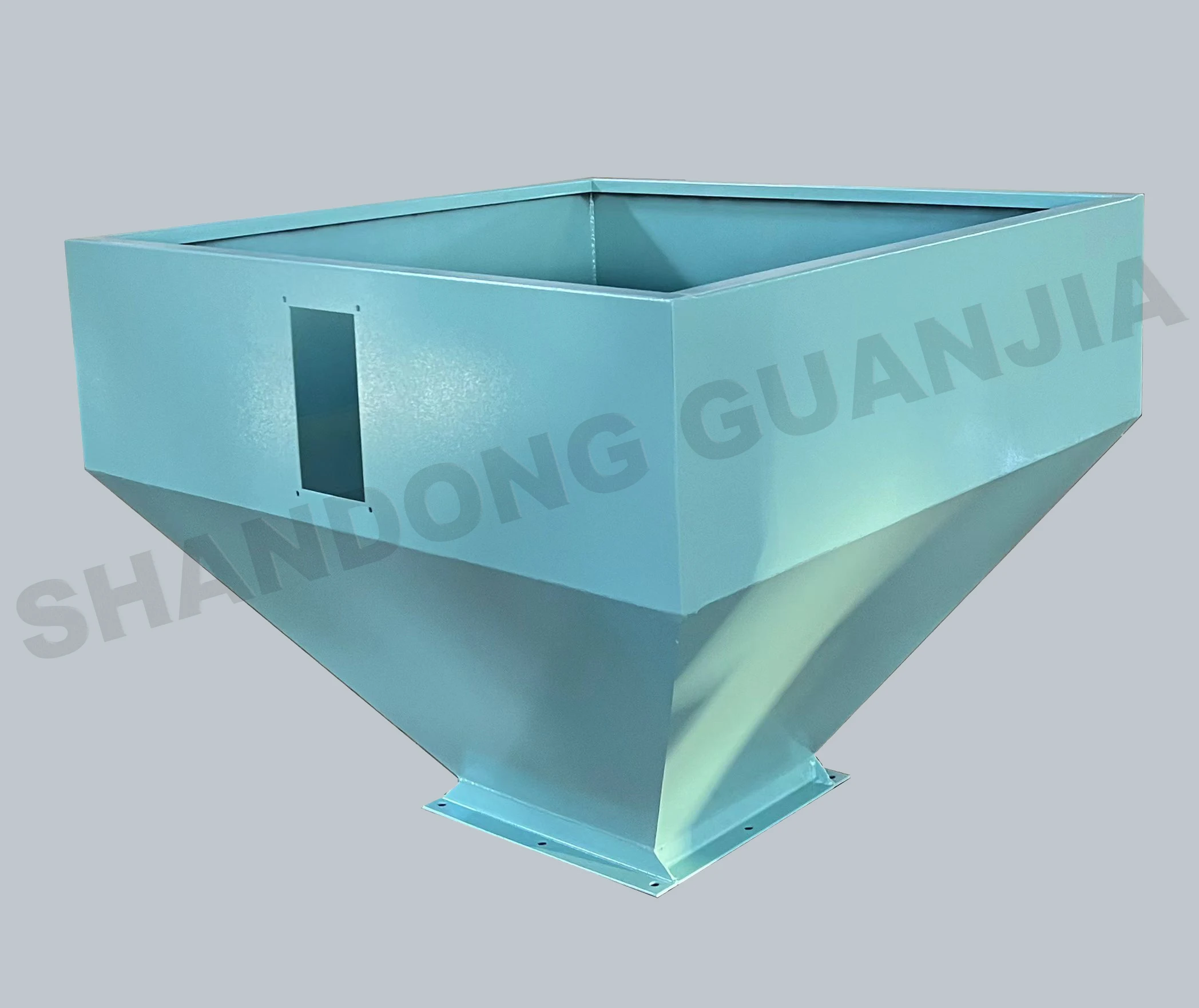

พารามิเตอร์ทางเทคนิคและลักษณะ DCS-Z-S-50 | ||||||||

วัสดุร่างกาย | เหล็กคาร์บอน ความหนาของแผ่น ≥ 2.5มม | |||||||

วัสดุถัง | สแตนเลสชิ้นส่วนติดต่อ304หรือที่กำหนดเอง | |||||||

น้ำหนักรวม | 900กก. | |||||||

ความจุบรรจุ | 400-600ถุง/ชม | |||||||

ปริมาณแม่นยำ | 5-50กก. หรือปรับแต่งเอง | |||||||

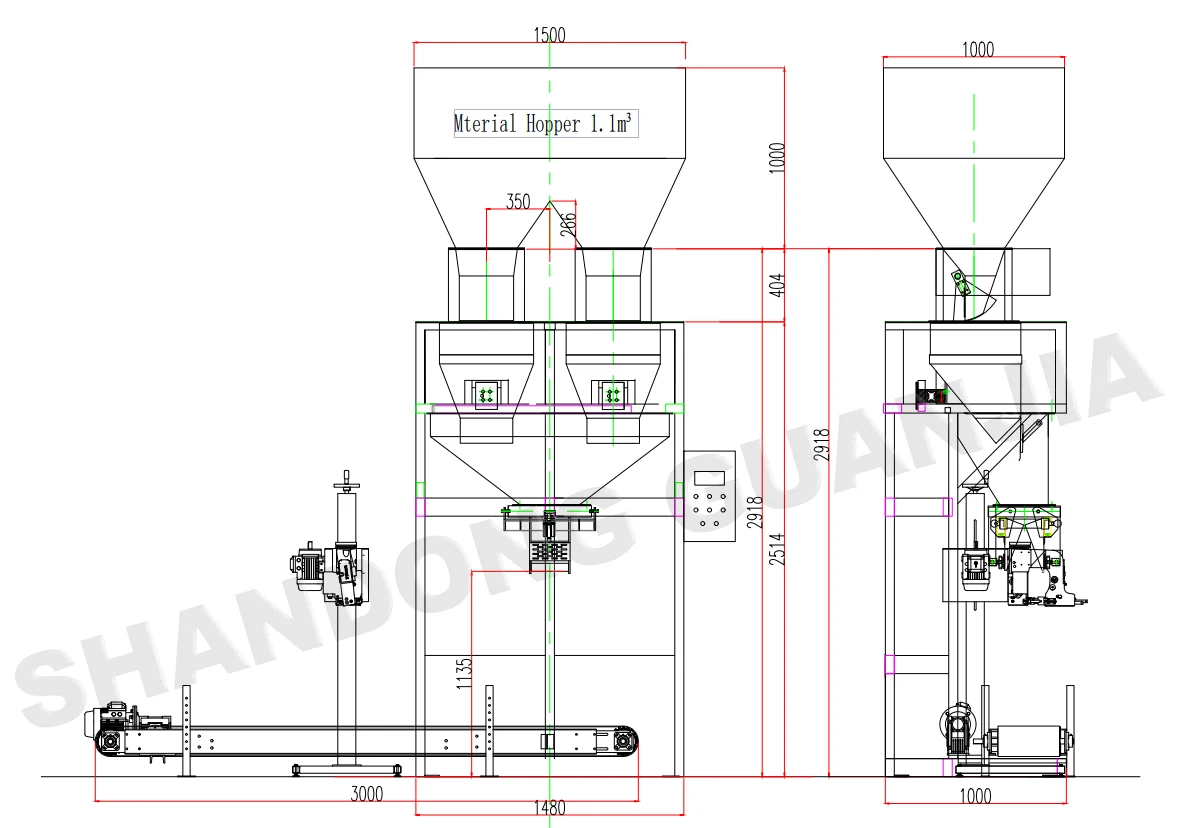

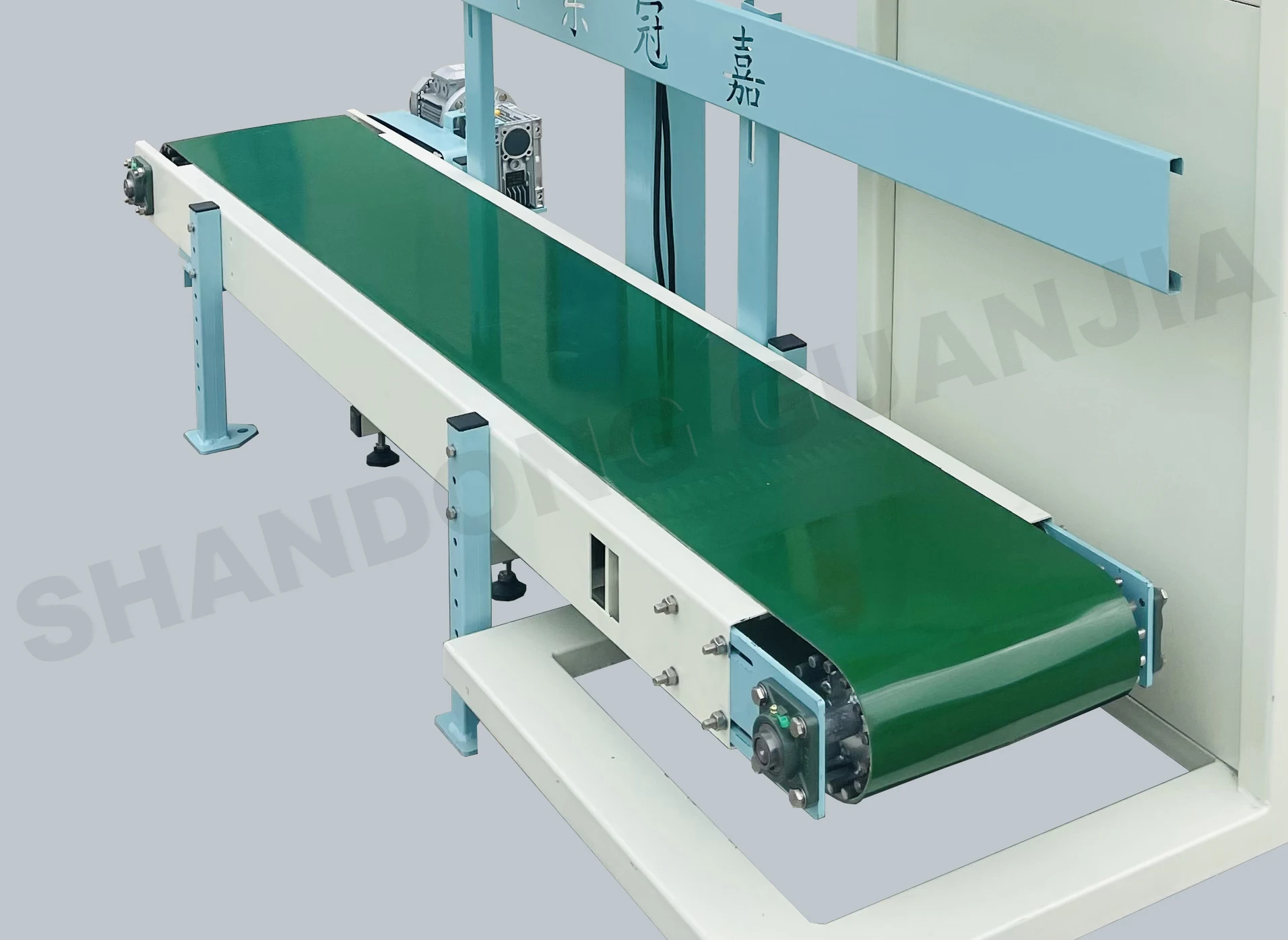

L × b× H (มม.) | 3000*1000*2900 | |||||||

CBM (M & sup3;) | 5M & sup3; (สำหรับการอ้างอิง) | |||||||

พลังงาน | 1.3kw | |||||||

แหล่งจ่ายไฟ | AC 220V/380V 50Hz หรือที่กำหนดเอง | |||||||

แหล่งอากาศ | 0.5 ~ 0.7MPa 0.36ม. & sup3;/นาทีเครื่องอัดอากาศ3KW(ไม่จำเป็น) | |||||||

บรรจุภัณฑ์ที่ถูกต้อง | ± 0.2% f.s | |||||||

อุณหภูมิสัมพัทธ์ | -10~40℃( 14-104℉) | |||||||

ถุงบรรจุภัณฑ์ | ถุงกระดาษ, ถุงผ้า, ถุงกระดาษคราฟท์, ถุงไนลอน, ถุงฟอยล์อลูมิเนียม, ถุงพลาสติก | |||||||

วิธีการปิดผนึก | จักรเย็บผ้า: ถุงกระดาษ, ถุงทอ, กระดาษงานฝีมือ, ถุงไนลอน (ตัวเลือก)เครื่องปิดผนึกร้อน: ถุงไนลอน, ถุงอลูมิเนียมฟอยล์, ถุงพลาสติก, ถุง PE | |||||||

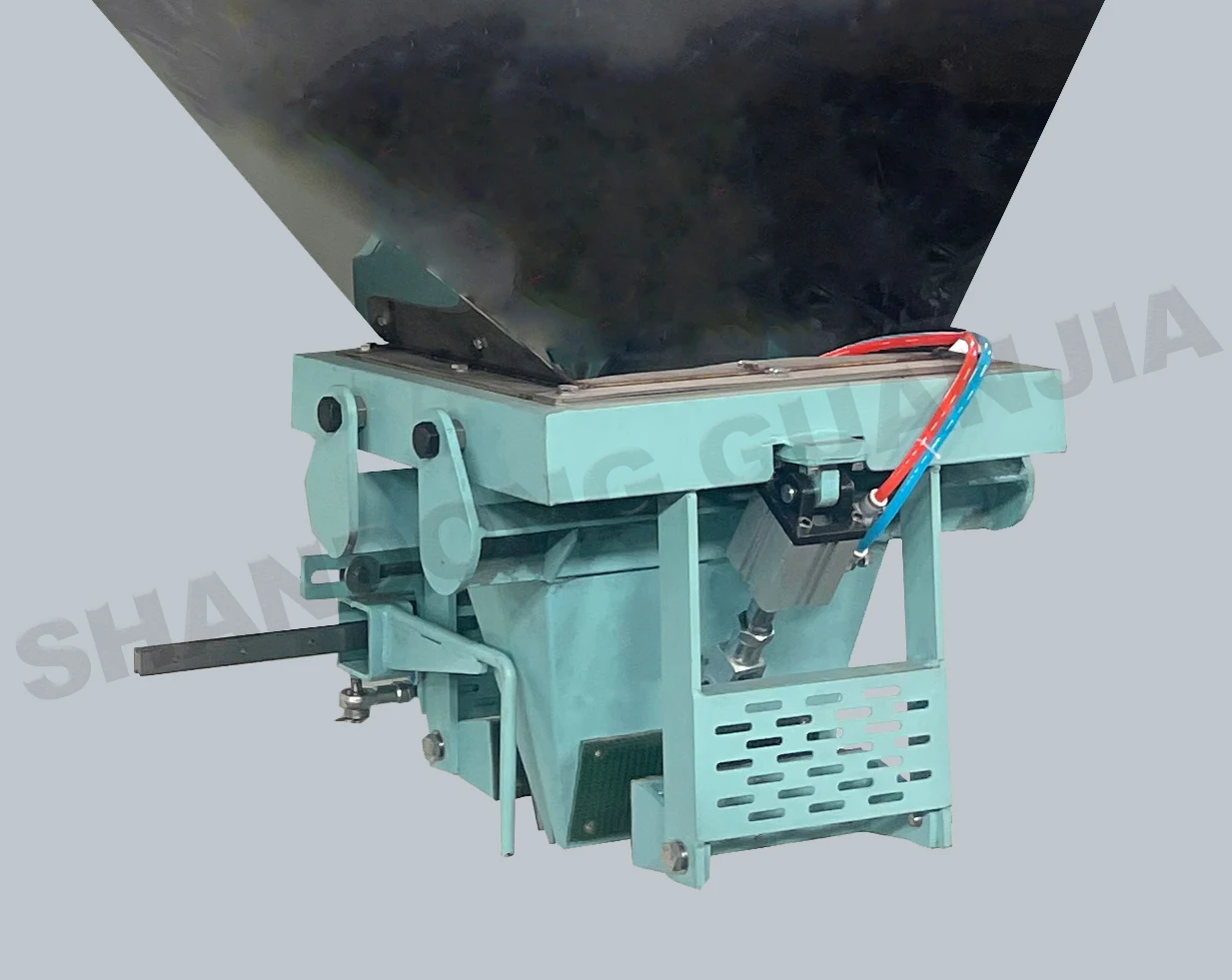

วัสดุการใช้งาน | เครื่องชั่งบรรจุภัณฑ์เชิงปริมาณ DCS-Z-SD-50เหมาะสำหรับบรรจุภัณฑ์ขนาดใหญ่ของวัสดุและสามารถนำมาใช้อย่างแพร่หลายในอุตสาหกรรมต่างๆเช่นอุตสาหกรรมธัญพืชอาหารและอุตสาหกรรมเคมี ประกอบด้วยอุปกรณ์เครื่องจักรกลอุปกรณ์ชั่งน้ำหนักอิเล็กทรอนิกส์และระบบควบคุมอัจฉริยะสำหรับเครื่องมือ อุปกรณ์กลไกรวมถึงกลไกการให้อาหาร, กลไกการหนีบถุง, ตัวรองรับทั้งภายในและภายนอกฯลฯระบบควบคุมประกอบด้วยเซ็นเซอร์และเครื่องมือชั่งน้ำหนักอัจฉริยะภายในระบบชั่งน้ำหนัก อุตสาหกรรมอาหาร:ถั่วเหลือง, ข้าว, ข้าวโพด, ข้าวสาลี, ถั่ว, มันฝรั่ง, ลูกอม อุตสาหกรรมเคมี: อนุภาคโพแทสเซียมคลอไรด์, แอมโมเนียมซัลเฟต, โพลีเอสเตอร์เรซิ่น, อนุภาคเรซิน, แมกนีเซียมซัลเฟต, อนุภาคยาง, แอมโมเนียมไฮไดโซเดียมฟอสเฟต, ยูเรียโพลีอะคริลาไมด์, ไดโซเดียมไฮโดรเจนฟอสเฟต, อนุภาคคาร์บอนกัมมันต์, อนุภาคขี้ผึ้ง Didi, แก้ว microspheres, สารทำละลายหิมะ, อนุภาคกรดฮิวมิก, ฯลฯ อุตสาหกรรมปุ๋ย: ปุ๋ย BB, ปุ๋ยผสม, ปุ๋ยสารประกอบ, ปุ๋ยไนโตรเจน, ปุ๋ยฟอสฟอรัส, ปุ๋ยโพแทสเซียม, diamine, ยูเรีย, ปุ๋ยอินทรีย์สารประกอบ, ปุ๋ยข้าวโพดสารประกอบฯลฯ อุตสาหกรรมก่อสร้าง: ทรายแม่น้ำทรายควอตซ์กรวดหินแท้ฯลฯ อุตสาหกรรมสัตว์เลี้ยง: อาหารสุนัขอาหารแมวครอกแมวฯลฯ | |||||||

คุณสมบัติการทำงาน | เครื่องบรรจุภัณฑ์ DCS-Z-SD-50เชิงปริมาณใช้การควบคุมอัตโนมัติสำหรับการให้อาหารที่รวดเร็วและช้าการป้อนปริมาณการหนีบถุงและการขนถ่ายยกเว้นกระเป๋าทำงาน ตั้งค่าพารามิเตอร์การควบคุมเช่นอัตราการป้อนเร็วและช้าและแสดงสัญญาณเตือนเกินพิกัดบนอุปกรณ์การสะสมน้ำหนักและเอาต์พุตการพิมพ์แบบอัตโนมัติที่กำหนดค่าได้ อุปกรณ์นี้ยังมีคุณลักษณะของความเร็วในการบรรจุที่รวดเร็วความแม่นยำของบรรจุภัณฑ์สูงเสถียรภาพที่ดีและใช้งานง่าย 1.ใช้สำหรับบรรจุภัณฑ์ผง ultrafine ด้านล่าง325ตาข่าย 2.ให้อาหารมังกรตัวเดียวแบบความเร็วสามระดับความแม่นยำของบรรจุภัณฑ์สูงและความเร็วที่รวดเร็ว 3.โครงสร้างเชิงกลโดยรวมได้รับการออกแบบอย่างสมเหตุสมผล 4.ตู้ควบคุมถูกปิดผนึกและเหมาะสำหรับสภาพแวดล้อมที่มีฝุ่นรุนแรง | |||||||

ทุกการชำระเงินที่คุณทำบน Cooig.com มีความปลอดภัยด้วยการเข้ารหัส SSL และโปรโตคอลการป้องกันข้อมูล PCI DSS ที่เข้มงวด

ขอรับเงินคืนหากคำสั่งซื้อของคุณไม่ได้จัดส่ง สูญหาย หรือสินค้าที่มาถึงมีปัญหาที่ตัวผลิตภัณฑ์