[CODE_4]: MEDIA_ELEMENT_ERROR: Format error

System Function | G code | ||||||||

Number of control axis | 3-5 Axis | Positioning | G00 | High-speed peck driling | G73 | ||||

Smallest programming: | 0.0001mm | Linear Interpolation | G01 | Counter tapping cycle | G74 | ||||

The most programming: | ±99999.999mm | Arc Interpolation | G02/G03 | Finishing boring cycle | G76 | ||||

Highest speed: | 60m/min | Dewell, Condition Pause | G04 | Cancel fixed cycle | G80 | ||||

Feed speed: | 0.001~15m/min | Memory Travel Detection | G12/G13 | Drilling cycle(spot drilling cycle) | G81 | ||||

Continuous manual: | one axis or multiple axis at the same time | Polar system command | G15/G16 | Drilling cycle(stepped hole boring cycle) | G82 | ||||

Line interpolation: | Straight line, arc, screw thread interpolation | Plane Selection | G17/G18/G19 | Peck drilling cycle | G83 | ||||

Tool compensation: | Length compensation、radius nose of tool compensation, tool wear compensation | Inch/Metric system | G20/G21 | CW Tapping cycle | G84 | ||||

Tool Setting | Positioning tool setting, trial cut tool setting, reference point tool setting | Inner circle groove roughing (CCW)/(CW) | G22/G23 | Boring cycle | G85 | ||||

Tool Management | Tool life management | Inner cycle finishing(CCW)/ (CW) | G24/G25 | Boring cycle | G86 | ||||

Tool post function | row tool post, electric tool post, hydraulic tool post(optional), servo tool post(optional) | Outer circle finishing (CCW) | G26 | Back Boring cycle | G87 | ||||

Spindle function: | Analog control、Soft tapping | Reference position return detection | G27 | Boring cycle | G88 | ||||

Handwheel function: | panel、handheld | Reference position return | G28 | Absolute programming | G90 | ||||

handwheel processing: | handwheel processing function | Return from reference position | G29 | Incremental Programming | G91 | ||||

Acceleration& Deceleration | Linear, S type, Exponential | 2nd,3rd,4th reference position return | G30 | Float coordinate system setting | G92 | ||||

Communication function: | USB interface | Skip function | G31 | Feed per minute | G94 | ||||

Compensation function: | Tool compansation、Radius compensation | Outer circle finishing (CW) | G32 | Feed per roatation | G95 | ||||

Edit program: | Metric/Inch | Rectangular groove roughing(CCW)/(CW) | G33/G34 | Constant cycle speed(cutting speed) | G96/G97 | ||||

Preread function: | Preread 10,000 short straight lines | Rectangular groove inner finishing(CCW)/(CW) | G35/G36 | Returned to initial plane in fixed cycle | G98 | ||||

Password protection: | Multilevel password protection | Rectangular outer finishing(CCW)/(CW) | G37/G38 | Return to R point in fixed cycle | G99 | ||||

Input/output: | I/O 24*24 | Corner offset arc interpolation | G39 | ||||||

PLC: | Inner Design, support edit online, support muti PLC program | Cutter compensation cancel | G40 | ||||||

Number of encoder: | 1 | Cutter compensation left/right | G41/G42 | ||||||

User macro program: | A/B type | Tool length compensation direction positive/negative | G43/G44 | ||||||

Electrical gear function: | Support | Tool length compensation cancel | G49 | ||||||

Limit | Hard limit, soft limit | Scaling cancel | G50 | ||||||

Diagnosis | IO diagnosis, PLC diagnosis | Scaling on | G51 | ||||||

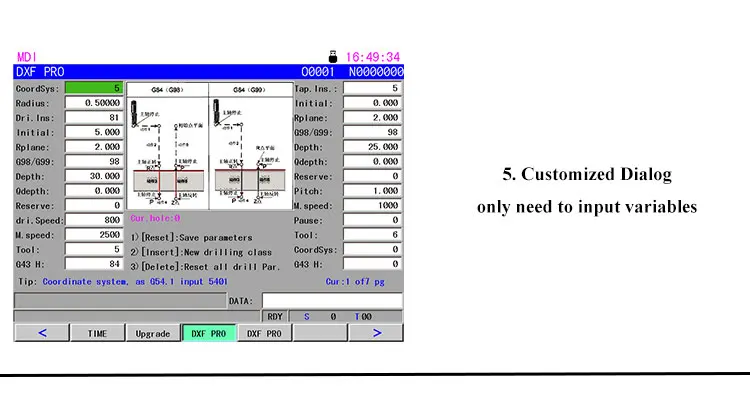

Customized User Dialog | Support | Machine coordinate system | G53 | ||||||

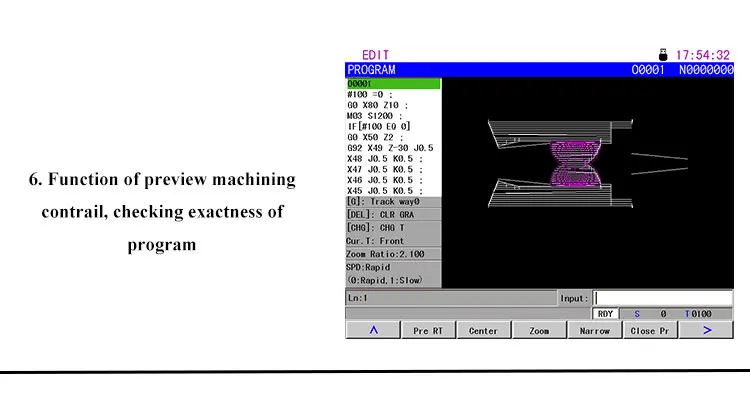

Program preview | Support | Workpiece coordinate | G54~G59, G54.1~G54.50 | ||||||

CAD to G code | Support(optional function) | Single direction positioning | G60 | ||||||

Multi-axis zero return | Support | Position mode selection | G61 | ||||||

Backlash compesnation | Support | Auto corner ratio | G62 | ||||||

Subpanel | Handwheel, Switch(optional) | Tapping mode | G63 | ||||||

Application: | Milling Machine, Milling Center | Cutting mode | G64 | ||||||

ATC Function | Linear type, Umbrella type, Mechanical Hand | Macro program | G65 | ||||||

Language | English, Russian(optional) | Coordinates rotate | G68/G69 | ||||||

คาดว่าคำสั่งซื้อของคุณจะถูกนำส่งก่อนวันที่กำหนดหรือรับการชดเชยความล่าช้า 10%

ทุกการชำระเงินที่คุณทำบน Cooig.com มีความปลอดภัยด้วยการเข้ารหัส SSL และโปรโตคอลการป้องกันข้อมูล PCI DSS ที่เข้มงวด

ขอรับเงินคืนหากคำสั่งซื้อของคุณไม่ได้จัดส่ง สูญหาย หรือสินค้าที่มาถึงมีปัญหาที่ตัวผลิตภัณฑ์

รับอะไหล่ทดแทนฟรีและความคุ้มครองการซ่อมแซม