[CODE_4]: MEDIA_ELEMENT_ERROR: Format error

เครื่องทำความสะอาดพัลส์ไฟเบอร์ประสิทธิภาพสูง500W รุ่นใหม่

เครื่องทำความสะอาดพัลส์ไฟเบอร์ประสิทธิภาพสูง500W รุ่นใหม่

อะไหล่ฟรี

อะไหล่ฟรี

Parameter:

|

Model

|

Fiber Laser Cleaning Machine

|

|

Laser source

|

MAX fiber laser

|

|

Laser power

|

500W |

|

Supply voltage

|

Single phase 220V ±10%, 50/60HZ AC |

|

Machine power consumption

|

2500W(within water chiller)

|

|

Output working method

|

Pulse/continuous

|

|

Output armor cable length

|

5m

|

|

cooling method

|

Water-cooled

|

|

Supply voltage

|

220V

|

|

Maximum power consumption

|

450W

|

|

Whether anti-high reflection

|

yes

|

|

Storage temperature range

|

10-60℃

|

|

Washing machine size

|

617*469*291mm

|

|

Package dimensions

|

750*580*500mm

|

|

weight

|

85Kg

|

|

Laser head weight

|

0.75Kg/0.9Kg/1.25Kg

|

|

Guarantee

|

2 year

|

Feature:

1. Laser cleaning is a "green" cleaning method that does not need to use any chemicals and cleaning fluids. The cleaned waste is basically solid powder, small in size, easy to store, recyclable, and can easily solve the problems caused by chemical cleaning. Environmental Pollution.

2 The laser is clear without grinding, non-contact, and no damage to the surface of the object.

3 Laser can be transmitted through optical fiber, coordinated with robots and robots, it’s convenient to realize long-distance operation, and can clean parts that are not easily reached by traditional methods. This can ensure the safety of personnel when used in some dangerous places.

4 Laser cleaning can remove various types of contaminants on the surface of various materials to achieve a cleanliness that cannot be achieved by conventional cleaning. It can also selectively clean the contaminants on the surface of the material without damaging the surface of the material.

5 Laser cleaning efficiency is high, saving time.

6 Although the initial one-time investment of the laser cleaning system is relatively high, the cleaning system can be used stably for a long time, and the operating cost is low. It only requires electricity per hour.

Advantage:

1. Advantages of environmental protection: laser cleaning is a "green" cleaning method. It does not need to use any chemical agent and cleaning solution. The cleaned waste is basically solid powder. It is small, easy to store and recyclable. It can easily solve the problem of environmental pollution caused by chemical cleaning.

2. Effect advantages: the traditional cleaning method is often contact cleaning, which has mechanical force on the surface of the cleaned object, damages the surface of the object or the cleaning medium is attached to the surface of the cleaned object,which cannot be removed and produces secondary pollution. The non grinding and non-contact of laser cleaning can solve these problems; Laser cleaning can remove various types of pollutants on the surface of various materials and achieve cleanliness that conventional cleaning cannot achieve. It can also selectively clean the pollutants on the material surface without damaging the material surface.

3. Control advantages: the laser can be transmitted through optical fiber, cooperate with manipulator and robot, conveniently realize long-distance operation, and can clean the parts that are not easy to reach by traditional methods, which can ensure the safety of personnel in some dangerous places.

4. Cost advantage: laser cleaning has high efficiency and saves time; Although the one-time investment in the purchase of laser cleaning system is high in the early stage, the cleaning system can be used stably for a long time and has low operation cost.

Application:

1,metal surface rust removal.

2,Surface paint removal and paint stripping treatment.

3,surface oil, stains, dirt cleaning.

4, surface plating, coating removal.

5,Welding surface/spraying surface pre-treatment.

6,Stone statue surface dust and adhesion removal.

7,Rubber mould residue cleaning.

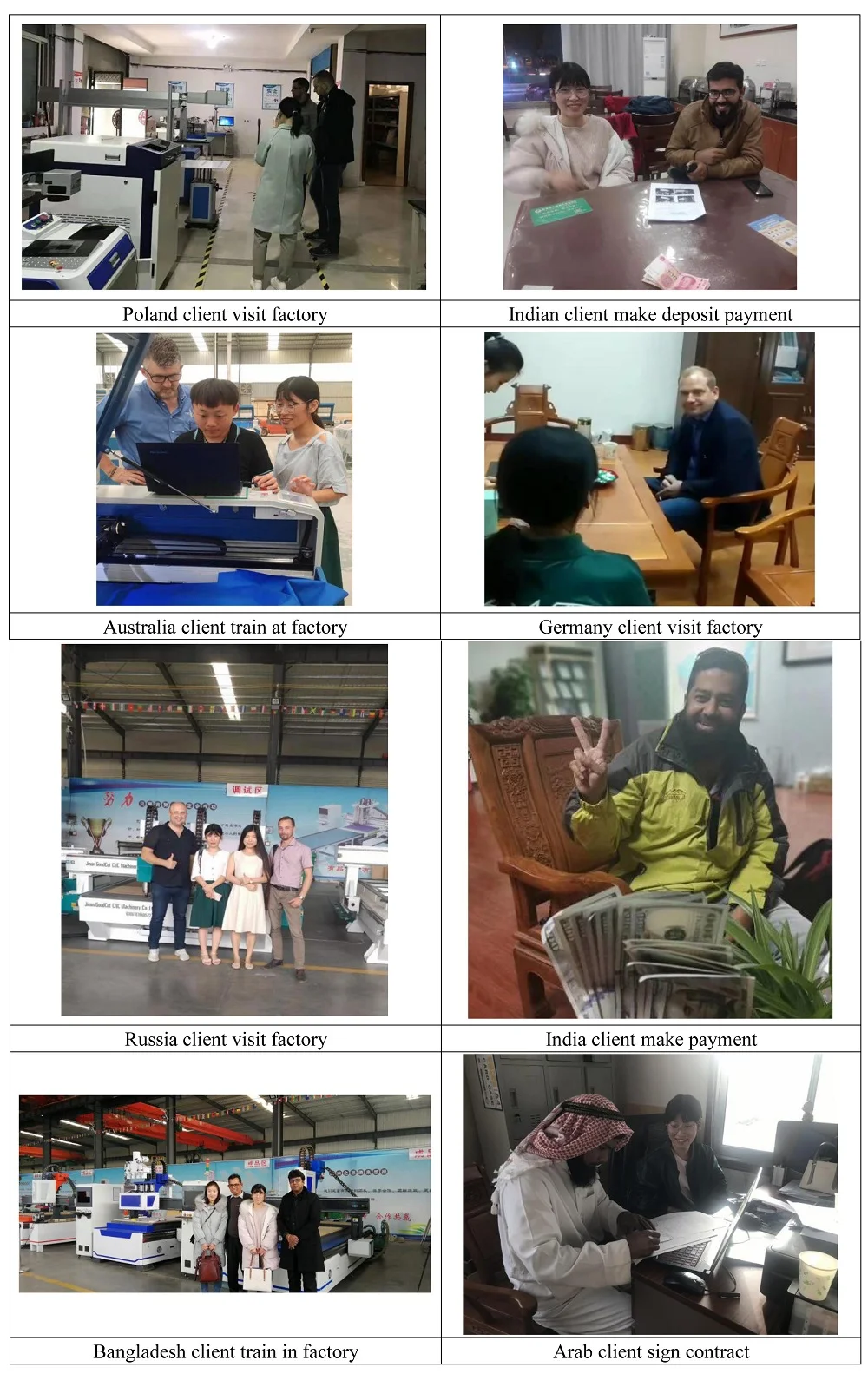

Jinan GoodCut CNC Machinery Co., Ltd.

The meaning of “GoodCut” brand: Good Quality, Good Price, Good Service

ทุกการชำระเงินที่คุณทำบน Cooig.com มีความปลอดภัยด้วยการเข้ารหัส SSL และโปรโตคอลการป้องกันข้อมูล PCI DSS ที่เข้มงวด

ขอรับเงินคืนหากคำสั่งซื้อของคุณไม่ได้จัดส่ง สูญหาย หรือสินค้าที่มาถึงมีปัญหาที่ตัวผลิตภัณฑ์