[CODE_4]: MEDIA_ELEMENT_ERROR: Format error

QS แนะนำปั๊มน้ำแบบดูดคู่

ปั๊มน้ำรุ่น QS เป็นปั๊มแรงเหวี่ยงแยกแนวนอนดูดสองขั้นตอนเดียวและใช้ในการขนส่งน้ำบริสุทธิ์และของเหลวทั้งลักษณะทางกายภาพและทางเคมีคล้ายกับของน้ำอุณหภูมิสูงสุดที่ต้องไม่เกิน80 ° C เหมาะสำหรับน้ำประปาและระบายน้ำในโรงงาน, เหมือง, เมืองและสถานีไฟฟ้า การระบายน้ำในดินที่มีน้ำขังและการชลประทานของที่ดินเพื่อเกษตรกรรมและโครงการไฮดรอลิกที่เอาใจใส่ รุ่นนี้ถูกนำมาใช้กันอย่างแพร่หลายในการเกษตรชลประทาน, ดับเพลิง, เหล็ก, อุตสาหกรรมพลังงาน

คุณสมบัติของปั๊มน้ำแบบดูดคู่ QS

ปั๊ม QS เป็นการดูดสองขั้นตอนเดียวในปั๊มแรงเหวี่ยงแบบเปิดใช้เพื่อขนส่งน้ำบริสุทธิ์และสมบัติทางกายภาพและทางเคมีคล้ายกับของเหลวน้ำอุณหภูมิสูงสุดต้องไม่เกิน125 ℃

(1) มี QS และ qsh สองประเภท

ดูจากเครื่องยนต์ไดรฟ์ทิศทางของปั๊ม qsh ทวนเข็มนาฬิกานั่นคือแรงดูดด้านซ้ายปล่อยในด้านขวา ทิศทางการหมุนของปั๊ม QS ประเภทตามเข็มนาฬิกานั่นคือการดูดในด้านขวาการปล่อยในด้านซ้าย นอกจากนี้ยังสามารถย้ายไดรเวอร์ไปยังขอบอื่นตามความต้องการของผู้ใช้ จากนั้นทิศทางการหมุนการดูดและทิศทางการไหลจะอยู่ในทิศทางตรงกันข้ามตามที่อธิบายไว้ข้างต้น

(2) จำหน่ายชุดเต็มปลอกปั๊มแรงเหวี่ยง, มอเตอร์, ข้อต่อ, เส้นผ่าศูนย์กลางขาเข้าน้อยกว่า200มม. ตรงกับฐานทั่วไป

(3) ปั๊มเป็นปลอกแยกตามแนวแกน

(4) ความจุขนาดใหญ่

QS ปั๊มน้ำแบบดูดคู่

ระบบชลประทาน:ชลประทานการเกษตร, ฟาร์มชลประทานและสเปรย์ชลประทาน

น้ำประปาทั่วไป:การไหลเวียนของระบบอาคาร HVAC, บริการเร่งน้ำ, หม้อไอน้ำ, บริการหมุนเวียนทั่วไปและอื่นๆ

การเกษตร/อาหาร/เครื่องดื่ม:การชลประทาน, น้ำประปา, การแปรรูปอาหาร, การแปรรูปเครื่องดื่ม, ปุ๋ย

การผลิต:พัดลมเยื่อกระดาษและกระดาษพลาสติกและยางโลหะและเหล็กโรงงานกระดาษเครื่องล้างอากาศบริการบัลลาสต์ทางทะเล

บรรเทาไฟ/ภัยพิบัติ:ปั๊มดับเพลิงการป้องกันอัคคีภัยการควบคุมน้ำท่วมการบรรเทาภัยพิบัติ

สาธารณูปโภคน้ำ/น้ำเสีย:สถานีผลิตไฟฟ้า, การแยกเกลือออกจากกัน, กังหันกู้คืนพลังงาน

เคมี/เหมืองแร่:โรงงานเคมี, โรงกลั่นน้ำมัน, การกระจายปิโตรเลียม, ไซต์ถ่านหิน, การสูบน้ำ

การก่อสร้าง

1.แบริ่ง2.กรอบซีลน้ำมัน3.ต่อมแบริ่ง4.ปลอกปั๊ม5.ต่อมบรรจุ6.packings 7.แหวนบรรจุ8.แขนบรรจุ9.แขนเพลา10.ฝาครอบปั๊ม11.ใบพัด12. ท่อซักผ้า13. แหวน14.แหวนซีลสำหรับปลอกปั๊ม15.ซับในซีลกล16. แหวน17.ซีลกล18.ต่อมซีลกล19. แหวนกักเก็บน้ำ20. โอริง21. ที่อยู่อาศัยแบริ่งที่ปลายขับเคลื่อน22.เพลา23ข้อต่อ24. คีย์ประเภท C 25. กรอบซีลน้ำมัน26.แหวนสำหรับเพลา

ข้อมูลจำเพาะ

| โมเดล | ความจุ | หัว | ความเร็ว (รอบต่อนาที) | พลังงาน | ประสิทธิภาพ (%) | Npsh (M) | น้ำหนัก (กก.) | ||

| (M3/ชม.) | (L/S) | เพลา | มอเตอร์ | ||||||

| 15QS-78 | 112-200 | 31-55 | 55-84 | 2900 | 30-51 | 45-55 | 68-75 | 5 | 150 |

| 150QS-50 | 120-220 | 31-61.2 | 35-52 | 2900 | 18.5-31.3 | 30-37 | 70-80 | 5 | 145 |

| 200QS-95 | 160-288 | 44.5-80 | 70.2-100 | 2900 | 60.8-88.6 | 90-110 | 62 | 5.5 | 245 |

| 200QS-63 | 180-351 | 50-97.5 | 37.5-69 | 2900 | 41-67.8 | 55-75 | 65-80 | 4.7-6.2 | 265 |

| 200QS-42 | 198-342 | 55-95 | 31-48 | 2900 | 30.5-40.2 | 37-45 | 76-82 | 4.8-8.2 | 219 |

| 250QS-65 | 342-612 | 95-170 | 50-71 | 1450 | 76.7-129.6 | 110-132 | 72-79 | 4 | 565 |

| 250QS-39 | 324-612 | 90-170 | 25-42.5 | 1450 | 40.2-67.7 | 55-75 | 75-86 | 4 | 428 |

| 250QS-24 | 342-576 | 95-160 | 17.4-27 | 1450 | 25.8-36.4 | 37-45 | 80-86 | 4 | 420 |

| 250QS-14 | 320-576 | 89-160 | 8.6-17.5 | 1450 | 15.4-22.1 | 22-30 | 75-85 | 4 | 405 |

| 300QS-90 | 540-936 | 150-260 | 57-98 | 1450 | 151-279 | 220-260 | 71-80 | 4.5-6.5 | 847 |

| 300QS-58 | 504-972 | 140-255 | 37-65 | 1450 | 99.2-168 | 180 | 78-84 | 5.5 | 572 |

| 300QS-19 | 504-935 | 140-260 | 11-23 | 1450 | 34.8-49.8 | 45-55 | 75-84 | 5.5 | 660 |

| 300QS-12 | 522-900 | 145-250 | 8-14.5 | 1450 | 22.4-33.1 | 30 | 75-80 | 5.5 | 660 |

| 350QS-125 | 740-1663 | 207-461 | 77-140 | 1470 | 313-620 | 500-680 | 70-81 | 6.5 | 1580 |

| 350QS-75 | 900-1440 | 250-400 | 54-80 | 1450 | 175-319 | 250-400 | 78-84 | 6.5 | 1200 |

| 350QS-44 | 864-1480 | 240-410 | 30-50 | 1470 | 121-188 | 160-220 | 79-84 | 6.5 | 1105 |

| 350QS-26 | 864-1440 | 240-400 | 16.5-32 | 1450 | 76.5-102 | 110-132 | 73-88 | 6.5 | 880 |

| 350QS-16 | 864-1440 | 240-400 | 10-20 | 1450 | 47.6-70 | 55-75 | 71-85 | 6.5 | 760 |

| 500QS-59 | 1150-2450 | 430-680 | 42-66 | 970 | 273-433 | 315-500 | 72-82 | 6 | 2750 |

| 500QS-35 | 1550-2410 | 430-670 | 31-40 | 970 | 137-247 | 240-280 | 80-88 | 6 | 2340 |

| 500QS-22 | 1296-2340 | 360-650 | 14-27 | 970 | 101-148 | 130-180 | 70-82 | 6 | 2010 |

| 500QS-20 | 2500-3800 | 694.4-1055 | 16-22 | 745 | 215-238.3 | 280-340 | 70-83 | 4.5-5.6 | 3030 |

| 500QS-13 | 1620-2325 | 450-646 | 10.6-15.2 | 970 | 70-79 | 110 | 85-89 | 6 | 2000 |

| 600QS-75 | 2300-3930 | 630-1092 | 49-80 | 960 | 442-730 | 550-900 | 85-90 | 7.5-8.7 | 4300 |

| 600QS-47 | 2502-3600 | 695-1000 | 32-56 | 970 | 392-460 | 450-550 | 80-88 | 7.5 | 3200 |

| 600QS-32 | 2304-3960 | 640-1100 | 20-37 | 970 | 228-310 | 280-380 | 84-89 | 7.5 | 2550 |

| 600QS-22 | 2340-3420 | 650-950 | 13-23.5 | 970 | 145-207 | 185-250 | 77-84 | 7.5 | 2500 |

| 800QS-76 | 4160-6600 | 1156-1722 | 63-82 | 740 | 976-1384 | 1400-1500 | 86-91 | 7.5-8 | 8000 |

| 800QS-32 | 4170-6460 | 1050-1795 | 23-33 | 730 | 391-580 | 450-630 | 78-84 | 6.5 | 5100 |

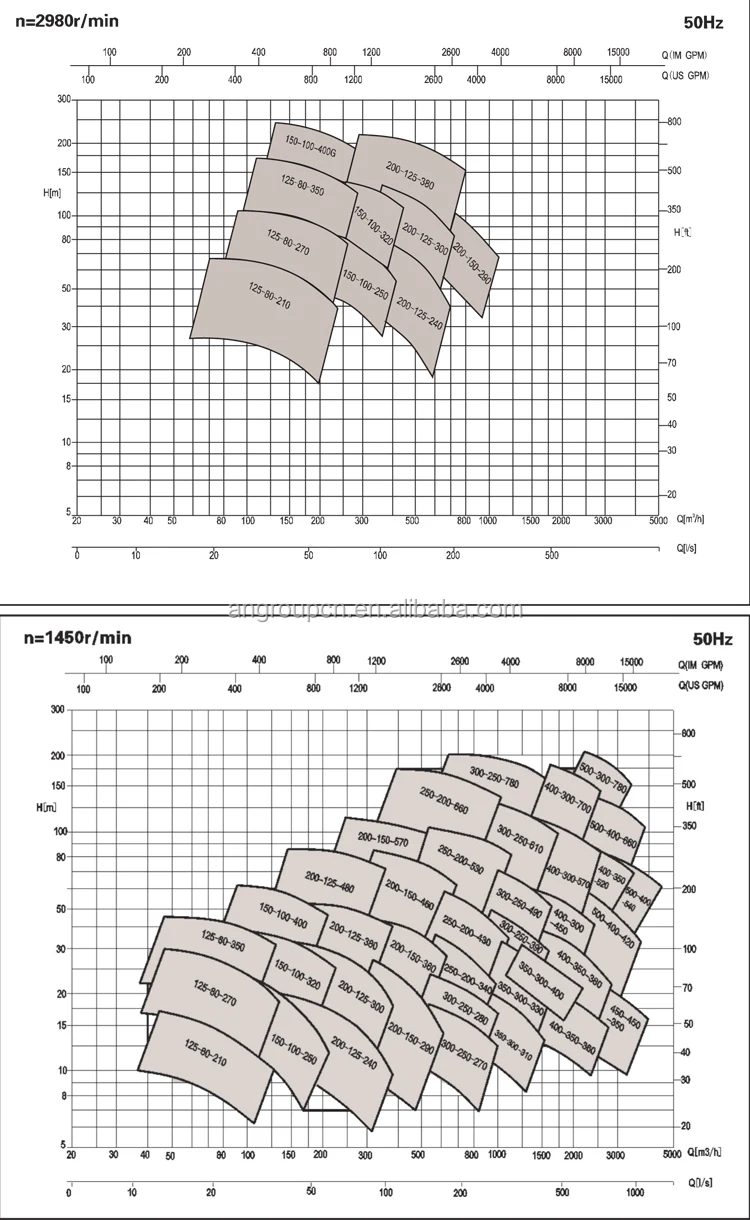

แผนภูมิประสิทธิภาพ

ประวัติโรงงาน:ก่อตั้งขึ้นในประเทศ1986

ประเภทธุรกิจ:ผู้ผลิตและผู้ส่งออก

ผลิตภัณฑ์หลัก:ปั๊มน้ำสารละลาย, ปั๊มน้ำเสียใต้น้ำ, ปั๊มสแตนเลส, ปั๊มน้ำ, ปั๊มทรายและกรวด, ปั๊มขุดลอก, ปั๊มเยื่อกระดาษ, ปั๊มน้ำทะเล, ปั๊มชลประทาน, ปั๊มน้ำดีเซล, ปั๊มเคมี, ปั๊มหมุนเวียนฯลฯ

ทุกการชำระเงินที่คุณทำบน Cooig.com มีความปลอดภัยด้วยการเข้ารหัส SSL และโปรโตคอลการป้องกันข้อมูล PCI DSS ที่เข้มงวด

ขอรับเงินคืนหากคำสั่งซื้อของคุณไม่ได้จัดส่ง สูญหาย หรือสินค้าที่มาถึงมีปัญหาที่ตัวผลิตภัณฑ์